What is an arc flash?

While an arc flash is sometimes used interchangeably with “arc fault”, an arc flash is more accurately defined as the light produced during an arc fault. An arc fault is a type of electrical fault that results from the breakdown of an insulating medium between two conductors where the energy is enough to sustain an arc across the insulator (often air) and can cause extreme amounts of light (arc flash), immense heat upwards of 19,000 degrees (substitute the symbol) C, and a resulting explosive pressure wave (arc blast). These forces combine to create a hazardous condition that can vaporize metal, destroy equipment, and pose a significant hazard to anyone in the vicinity.

What causes an arc flash?

An arc flash happens when electric current flows through an air gap between conductors. There are several ways this can happen but the most common occurrence is when conductor insulation is warn or broken down.

What is an arc-flash relay?

Arc-flash relays are microprocessor-based devices that use optical sensors to detect the onset of a flash. The sensors are strategically placed in various cubicles or drawers inside the switchboard. Installing an arc-flash relay to rapidly detect developing arc flashes greatly reduces the total clearing time and the amount of energy released through an arcing fault. In turn, there is less damage to equipment and fewer and less severe injuries to nearby personnel.

Why are arc-flash relays important?

Arc-flash relays are a necessary component in an electrical cabinet because they reduce the amount of incident energy in the system. While an arc-flash relay cannot prevent an arc flash from happening, it will protect critical assets and workers’ safety by reducing the severity. An arc-flash relay is an integral part of an arc-flash protection scheme that can minimize damage, and save money, time, and lives.

How much energy is in a typical arc-flash incident?

A phase-to-phase fault on a 480-volt system with 20,000 amperes of fault current provides 9,600,000 watts of power. If there is no arc protection and the fault lasts for 200 milliseconds before the overcurrent protection clears it, then 2 megajoules of energy will be released, which corresponds roughly to a stick of dynamite.

The energy formula for an arc flash is:

Energy = voltage x current x time

480 V x 20,000 A x 0.2 s = 1,920,000 J

For a given system voltage, two factors can be adjusted to reduce arc-flash energy: time and current

Time can be reduced by using an arc-flash relay, such as the PGR-8800 or AF0500, to rapidly detect an electric arc flash. An arc-flash relay causes the connected circuit breaker to trip at its instantaneous speed, overriding any inverse-time delay. Current can be reduced by using current-limiting fuses or, in the case of phase-to-ground faults, by using high-resistance grounding.

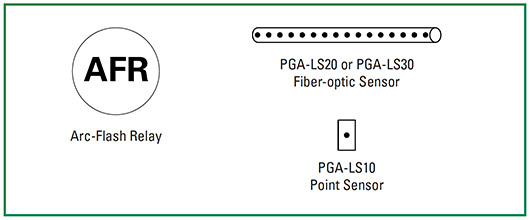

What is the electrical symbol of an arc-flash relay?

Although there is no formal symbol, Littelfuse uses the symbol:

How long has Littelfuse manufactured arc-flash relays?

Littelfuse acquired arc-flash technology from Selco in 2011, which had been manufacturing arc-flash relays for almost 20 years. The product was launched in North America in August of 2011. Littelfuse has numerous installations throughout the world and an estimated 18,000 arc-flash relays are installed world-wide.

What are the key considerations when choosing an arc-flash relay?

The most important aspects of arc-flash relays are

- reaction time,

- trip reliability,

- ease of installation,

- sensor flexibility,

- software,

- sensor design,

- avoidance of nuisance tripping, and

- scalability.

Gain a deeper understanding of which features to consider when selecting an arc-flash relay with the white paper, Key Considerations to Selecting an Arc-Flash Relay.

What are the consequences of an arc flash?

Arcing and electric arc flashes are uncontrolled, intense, luminous discharges of electrical energy that occur when electric current flows across what is normally an insulating medium. The most common cause of arc faults is insulation failure. These failures may be caused by defective or aging insulation material, poor or incorrect maintenance, dust, moisture, vermin, and human error (such as touching a test probe to the wrong surface or a tool slipping and touching live conductors). Arc-flash events are dangerous, and potentially fatal, to personnel. According to OSHA, industrial arc flash events cause about 80 % of electrically-related incidents and fatalities among qualified electrical workers. Even if personnel injuries are avoided, an arc flash can destroy equipment, resulting in costly replacement and downtime.